Meals grade hose is an indispensable element within the meals and beverage business, taking part in a vital position in sustaining meals security and hygiene all through the processing chain. These hoses are particularly designed to satisfy stringent regulatory requirements, guaranteeing that meals merchandise are shielded from contamination and degradation.

This complete information delves into the intricacies of meals grade hose, exploring their materials composition, design, cleansing and upkeep protocols, and correct storage and dealing with practices. By understanding these points, meals processors can make sure the longevity and optimum efficiency of their meals grade hoses, safeguarding the integrity and high quality of their merchandise.

Business Functions

Meals grade hoses play a vital position within the meals and beverage business, guaranteeing the secure and hygienic dealing with of meals merchandise. They’re designed to satisfy stringent regulatory requirements, stopping contamination and preserving the standard of meals.

Meals Processing

- Meals grade hoses are utilized in numerous meals processing operations, together with ingredient dealing with, mixing, and packaging. They make sure the secure switch of meals merchandise with out compromising their integrity.

- These hoses are immune to chemical substances and warmth, permitting them to face up to the cruel circumstances typically encountered in meals processing environments.

Beverage Manufacturing, Meals grade hose

- Meals grade hoses are important in beverage manufacturing, from fermentation to bottling. They’re used to switch liquids, gases, and components all through the manufacturing course of.

- The hoses’ non-porous floor prevents the absorption of flavors or odors, guaranteeing the preservation of beverage high quality.

Dairy Business

- Within the dairy business, meals grade hoses are used to deal with milk, cream, and different dairy merchandise. They’re designed to face up to the excessive temperatures and pressures concerned in pasteurization and different dairy processing operations.

- These hoses stop the expansion of micro organism and preserve the freshness and high quality of dairy merchandise.

Materials Composition and Requirements: Meals Grade Hose

Meals grade hoses play a vital position in guaranteeing the security and high quality of meals merchandise. To satisfy this function, they need to adhere to strict regulatory requirements and be constructed from supplies which might be inert, non-toxic, and immune to corrosion and degradation.

The most typical supplies utilized in meals grade hoses embrace:

- Stainless Metal:Extremely corrosion-resistant, sturdy, and simple to wash. Meets the requirements of the American Society of Mechanical Engineers (ASME) and the Worldwide Group for Standardization (ISO).

- Ethylene Propylene Diene Monomer (EPDM):An artificial rubber that’s immune to warmth, ozone, and chemical substances. Complies with the Meals and Drug Administration (FDA) and the European Meals Security Authority (EFSA) laws.

- Polytetrafluoroethylene (PTFE):A fluoropolymer identified for its distinctive chemical inertness and high-temperature resistance. Meets the FDA and ISO requirements.

Along with materials composition, meals grade hoses should additionally adjust to numerous regulatory requirements and certifications. These requirements be certain that the hoses are manufactured and examined to satisfy the best ranges of security and high quality.

- FDA:The FDA regulates the supplies utilized in meals contact functions in america.

- ISO:The ISO develops worldwide requirements for meals security and high quality administration programs.

- NSF Worldwide:An impartial group that certifies meals grade hoses and different food-related merchandise.

By assembly these regulatory necessities and utilizing authorized supplies, meals grade hoses guarantee the security and integrity of meals merchandise all through the manufacturing, processing, and distribution processes.

Design and Building

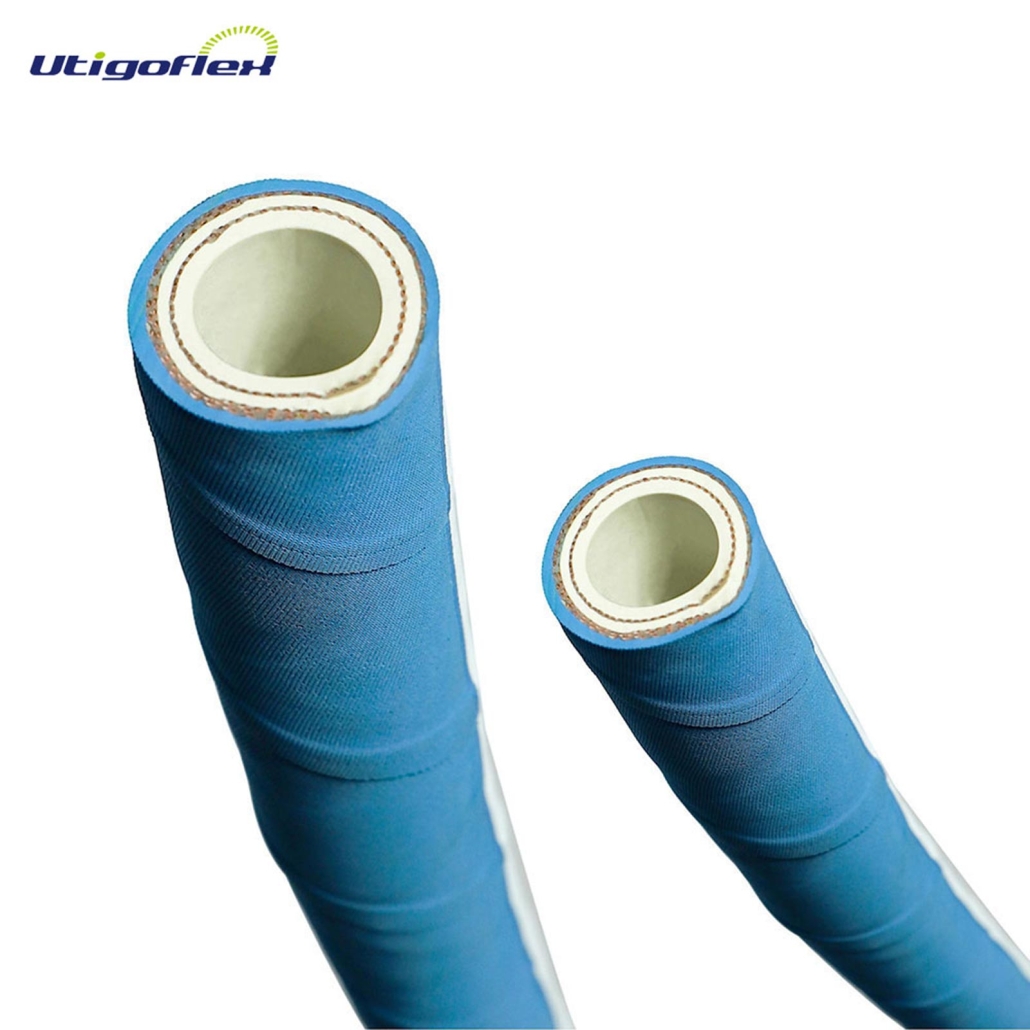

Meals grade hoses are meticulously designed and constructed to make sure their suitability to be used within the meals business. These hoses exhibit distinctive flexibility, permitting them to be simply maneuvered and put in in complicated piping programs. Their strong development ensures sturdiness, withstanding the trials of business meals processing environments.

The design of meals grade hoses prioritizes temperature resistance, enabling them to deal with a variety of temperatures encountered in meals processing functions. This versatility permits them to securely convey fluids starting from chilly drinks to sizzling sanitizing options.

Building Methods

Meals grade hoses are constructed utilizing superior methods to make sure they meet stringent meals security requirements. These methods embrace:

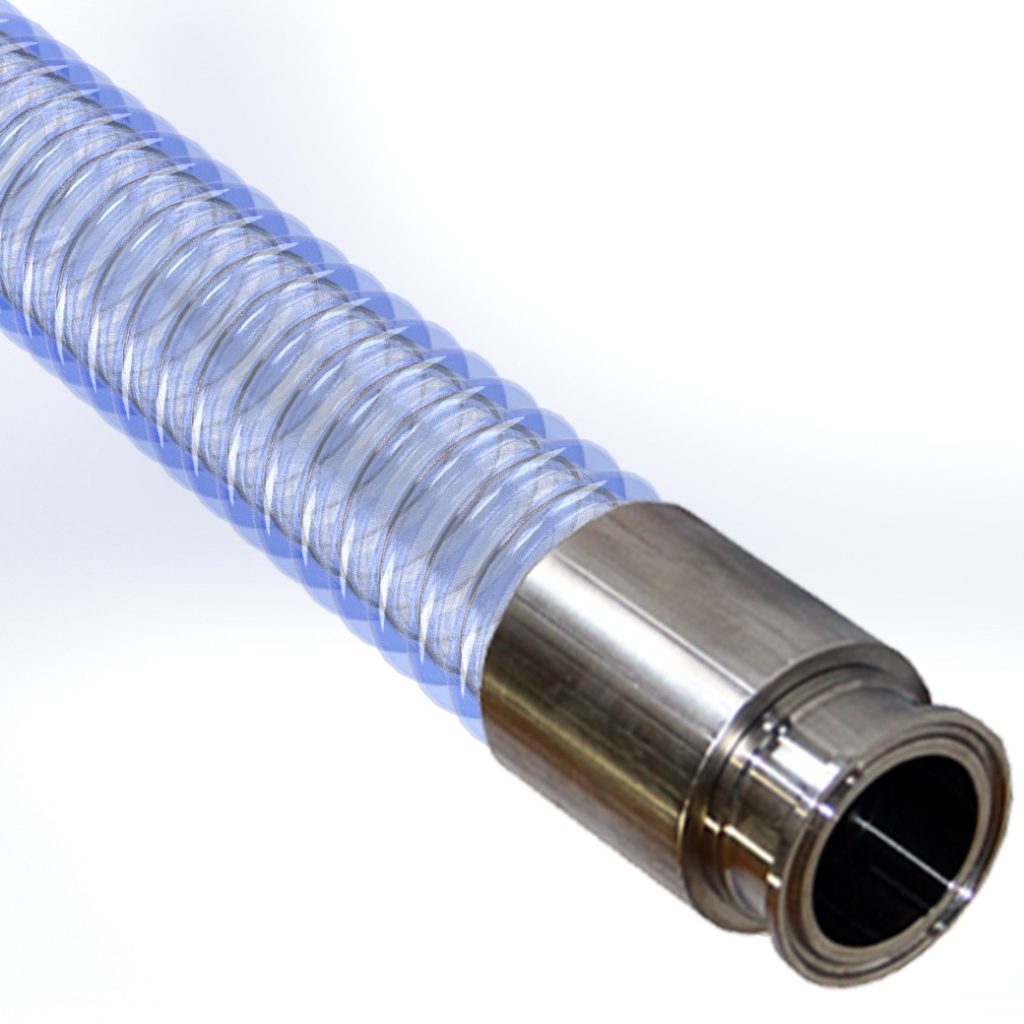

- Clean Internal Floor:The inside of meals grade hoses is meticulously crafted to be easy and freed from imperfections, minimizing the chance of micro organism or particles accumulation.

- Non-Poisonous Supplies:The supplies utilized in meals grade hoses are fastidiously chosen to make sure they’re non-toxic and don’t leach dangerous substances into the meals merchandise.

- Sturdy Reinforcement:Meals grade hoses are bolstered with high-strength supplies, similar to stainless-steel or artificial fibers, to face up to stress and stop kinking or rupture.

- Leak-Proof Fittings:The fittings used to attach meals grade hoses are designed to be leak-proof, guaranteeing a safe and sanitary connection.

Cleansing and Upkeep

Correct cleansing and upkeep are important to make sure the security and longevity of meals grade hoses. Common cleansing removes contaminants and micro organism that may accumulate over time, stopping the chance of meals contamination.

Cleansing Strategies

The best cleansing methodology for meals grade hoses will depend on the particular utility and kind of hose. Widespread cleansing strategies embrace:

- Chemical Cleansing:Utilizing food-grade detergents or sanitizing options to take away natural matter and micro organism.

- Steam Cleansing:Exposing the hose to high-temperature steam to kill micro organism and take away cussed residues.

- Mechanical Cleansing:Utilizing brushes or different mechanical gadgets to bodily take away particles from the hose floor.

Detergent Choice

Meals-grade detergents particularly designed for cleansing meals contact surfaces must be used. These detergents are non-toxic and meet business requirements for meals security. Keep away from utilizing harsh chemical substances or abrasive cleaners that may injury the hose materials.

Inspection and Monitoring

Common inspection of meals grade hoses is essential to establish any injury or put on that would compromise meals security. Test for cracks, leaks, or different defects that will enable contaminants to enter the hose. Maintain a file of inspections and cleansing procedures for traceability and compliance functions.

Storage and Dealing with

Correct storage and dealing with of meals grade hoses are important to keep up their longevity, efficiency, and sanitary integrity. Neglecting these points can result in untimely deterioration, contamination, and compromised meals security.

Correct Storage

- Retailer hoses in a cool, dry, and well-ventilated space away from direct daylight and excessive temperatures.

- Maintain hoses coiled loosely to stop kinking and injury.

- Droop hoses off the bottom or hold them on racks to permit for correct airflow and stop moisture accumulation.

- Keep away from storing hoses close to sharp objects or chemical substances that would puncture or injury them.

Correct Dealing with

- Deal with hoses fastidiously, avoiding extreme bending or twisting that would injury the inside lining.

- Don’t drag hoses throughout tough surfaces, as this may trigger abrasion and put on.

- Use correct fittings and connections to make sure safe attachment and stop leaks.

- Frequently examine hoses for any indicators of harm or put on, and exchange them promptly if essential.

Important FAQs

What are the widespread supplies utilized in meals grade hoses?

Meals grade hoses are usually constituted of supplies similar to EPDM, nitrile, and polyurethane, that are FDA-approved and meet regulatory requirements for meals contact.

How typically ought to meals grade hoses be cleaned and inspected?

Common cleansing and inspection of meals grade hoses are essential to keep up meals security. The frequency of cleansing will depend on the particular utility and utilization, however it’s usually really useful to wash hoses every day or as per the producer’s tips.

What are the potential dangers related to improper storage or dealing with of meals grade hoses?

Improper storage or dealing with of meals grade hoses can result in contamination, injury, or untimely failure. You will need to retailer hoses in a clear, dry place, away from direct daylight and excessive temperatures.